When did pins begin to be mass produced?

June 22, 1832 — How do you make a pin? John Howe was the first to figure it out, and today in 1832 patented the pin manufacturing machine.

June 22, 1832 — How do you make a pin? John Howe was the first to figure it out, and today in 1832 patented the pin manufacturing machine.

Born in Ridgefield, Connecticut in 1793, he trained as a doctor, working at the New York Almshouse as a resident physician. There, he first observed pins being made by a manual process.

Historians explain that the shaping of a straight pin at that time required 18 separate steps. Howe’s first pin machine shortened the process.

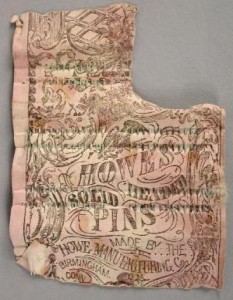

He received backing from a group of New York merchants to establish the Howe Manufacturing Company in 1833. After three years of production in New York, the company moved to the Birmingham section of Derby, Connecticut, where it became one of the largest pin manufacturers in the United States during the 19th century.

Between 1790-1873, the Howe Manufacturing Company held 9 of the 47 patents for the manufacturing of pins granted by the US Patent Office. Howe himself held two for the design of the pin machines, and seven were granted to employees of the company for the pin sticking machines used to package the manufactured pins.

Sources

Words of Wisdom

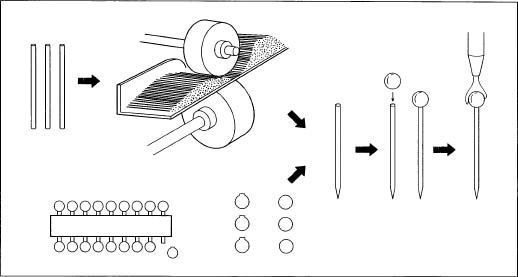

Blunt wire with an international steel regulation of ISR 9002 is generally used to make straight pins. To create the wire, a bar of steel is heated to a temperature of 2,200°F (1,200°C), rolled into a long thin rod, coiled, and then allowed to cool. The heating causes an oxide coating to form on the wire. To remove this coating, the wire is immersed in an acid bath, then rinsed in water.

The cleaned wire is inserted into a drawing block that pulls the wire through a die whose opening is smaller in diameter than that of the wire. Thus the wire is reduced in diameter and increased in length. The drawing is undertaken several times until the desired diameter is obtained. As it comes off of the last stage of drawing, the steel is coiled. The dies are coated with grease or soap to protect the wire as it passes through. This lubrication process also removes defects and gives the wire a smooth finish.

Nickel is a silvery chemical element extracted from the earth's crust. It is combined with sulfate to create a solution for coating the pins to keep them from rusting. Learn more at http://www.madehow.com/Volume-7/Straight-Pin.html.